Ladle Comprehensive Management System, Negotiable

Yalova |

11 January 2024, sales463205643, №104696, views: 470

Overview:

In the steelmaking production process, the ladle is the key equipment for holding molten steel, secondary refining, and continuous pouring. In a modern steelmaking plant, refractory materials are required for converters, refining, and ladles. In the steelmaking process, ladle is the main equipment for using and consuming refractory materials. Improving the service life of ladles and reducing refractory consumption is the key technology for steelmaking plants to save costs and reduce energy consumption for green production.

In order to ensure the orderly operation of the ladle, save the consumption of refractory materials, prolong the service life of the ladle, and ensure the safe operation of the ladle, Wuhan CenterRise M&C Engineering CO. developed and launched the LDT-N200 integrated management system for the ladle.

Introduction:

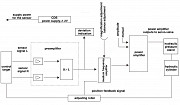

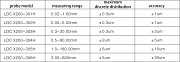

LDT-N200 ladle integrated management system integrates LDT-L200 ladle lining thickness gauge, TBP-S300 ladle, tundish baking temperature and leakage monitoring system, RFD -C100 metallurgical electronic positioning system, and also integrates SQL Server database and NeuralWare (American computer software company) neural network software NeuralWorks to realize intelligent and optimized management of ladles.

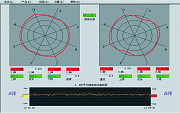

LDT-L200 ladle lining thickness gauge uses a laser area array scanning sensor to accurately measure the real-time thickness of the ladle lining, calculate the lining loss, and predict the service life of the ladle.

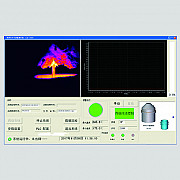

TBP-S300 ladle, tundish baking temperature and leakage monitoring system uses infrared thermal imaging camera and embedded armor wire system to comprehensively monitor and prevent ladle leakage.

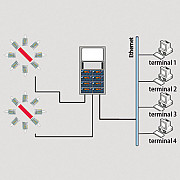

RFD-C100 metallurgical electronic positioning system installs RFID electronic tags on all ladles to realize full-time and full-space ladle positioning and tracking.

LDT-S200 ladle optimization control and analysis software, based on SQL Server database, B/S network structure, realizes online management of ladles, and adopts BP neural network system to realize intelligent optimization control of ladles.

LDT-N200 ladle integrated management system can realize ladle age management based on ladle lining data and neural network algorithm, safety process control of ladle turnover and use, full-time tracking management of steelmaking production and full-space tracking management of ladle use and provide optimal control and management of steelmaking production and ladle maintenance. Comprehensive ladle measurement and monitoring, ladle positioning and management, and data management and optimization enable the LDT-N200 ladle integrated management system to fully realize ladle entire process management, optimize the service life of ladles, and comprehensively reduce the cost of refractory materials.

The features:

Using a lining thickness gauge to measure the thickness of the ladle lining

Using infrared thermal imaging camera/embedded armor wire to realize ladle leakage detection

Using RFID/number plate recognition to realize the location management of ladles

Ladle age management system based on overall tracking

Overall (full-time full-space) ladle management system based on database

Provide overall production scheduling data

Using neural network to predict ladle service life based on big data

Ladle Optimal Scheduling System based on database and ladle service life

Increase the service life of ladle by 12%-20%

Reduce the use of refractory materials more than 15%

Realize orderly management of ladle baking

Realize full space and full time domain control

Reduce the costs of ladle management and maintenance

Improve the efficiency of ladle turnover operation

In the steelmaking production process, the ladle is the key equipment for holding molten steel, secondary refining, and continuous pouring. In a modern steelmaking plant, refractory materials are required for converters, refining, and ladles. In the steelmaking process, ladle is the main equipment for using and consuming refractory materials. Improving the service life of ladles and reducing refractory consumption is the key technology for steelmaking plants to save costs and reduce energy consumption for green production.

In order to ensure the orderly operation of the ladle, save the consumption of refractory materials, prolong the service life of the ladle, and ensure the safe operation of the ladle, Wuhan CenterRise M&C Engineering CO. developed and launched the LDT-N200 integrated management system for the ladle.

Introduction:

LDT-N200 ladle integrated management system integrates LDT-L200 ladle lining thickness gauge, TBP-S300 ladle, tundish baking temperature and leakage monitoring system, RFD -C100 metallurgical electronic positioning system, and also integrates SQL Server database and NeuralWare (American computer software company) neural network software NeuralWorks to realize intelligent and optimized management of ladles.

LDT-L200 ladle lining thickness gauge uses a laser area array scanning sensor to accurately measure the real-time thickness of the ladle lining, calculate the lining loss, and predict the service life of the ladle.

TBP-S300 ladle, tundish baking temperature and leakage monitoring system uses infrared thermal imaging camera and embedded armor wire system to comprehensively monitor and prevent ladle leakage.

RFD-C100 metallurgical electronic positioning system installs RFID electronic tags on all ladles to realize full-time and full-space ladle positioning and tracking.

LDT-S200 ladle optimization control and analysis software, based on SQL Server database, B/S network structure, realizes online management of ladles, and adopts BP neural network system to realize intelligent optimization control of ladles.

LDT-N200 ladle integrated management system can realize ladle age management based on ladle lining data and neural network algorithm, safety process control of ladle turnover and use, full-time tracking management of steelmaking production and full-space tracking management of ladle use and provide optimal control and management of steelmaking production and ladle maintenance. Comprehensive ladle measurement and monitoring, ladle positioning and management, and data management and optimization enable the LDT-N200 ladle integrated management system to fully realize ladle entire process management, optimize the service life of ladles, and comprehensively reduce the cost of refractory materials.

The features:

Using a lining thickness gauge to measure the thickness of the ladle lining

Using infrared thermal imaging camera/embedded armor wire to realize ladle leakage detection

Using RFID/number plate recognition to realize the location management of ladles

Ladle age management system based on overall tracking

Overall (full-time full-space) ladle management system based on database

Provide overall production scheduling data

Using neural network to predict ladle service life based on big data

Ladle Optimal Scheduling System based on database and ladle service life

Increase the service life of ladle by 12%-20%

Reduce the use of refractory materials more than 15%

Realize orderly management of ladle baking

Realize full space and full time domain control

Reduce the costs of ladle management and maintenance

Improve the efficiency of ladle turnover operation

Share with your friends!

Related Ads

Tools

Negotiable

Yalova

15 January

2024

2024

Location: Yalova, Turkey

Category: Items For Sale, Tools

Post ID: 104696